Unsaturated Polyester Resin

Polyester Resin: Affordable, Durable, and Versatile for a Wide Range of Applications

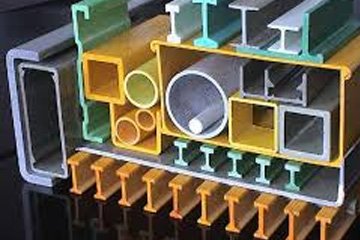

Polyester resin is a popular thermosetting resin known for its cost-effectiveness, ease of use, and excellent performance across a wide range of applications. Made by polymerizing a mixture of organic acids (like maleic or phthalic acid) with alcohols (such as ethylene glycol), polyester resins offer a balance of strength, flexibility, and chemical resistance. They are widely used in the production of composites, coatings, and other industrial materials.

- Cost-Effective:Polyester resins are generally less expensive compared to other types of resins, making them a budget-friendly option for many applications without compromising on performance.

- Good Strength and Durability: Polyester resins offer good mechanical strength and are resistant to abrasion, making them ideal for use in construction, automotive, and marine applications.

- Chemical Resistance:While not as resistant as epoxy or vinyl ester resins, polyester resins still provide good resistance to a variety of chemicals, making them suitable for use in a range of environments.

- Ease of Use:Polyester resins are easy to work with and can be cured quickly at room temperature with the addition of a catalyst, making them ideal for fast-paced production processes.

Polyester resins typically cure through a chemical reaction involving a catalyst, such as methyl ethyl ketone peroxide (MEKP), which triggers polymerization. The process is fast, allowing for quick turnaround times in production and manufacturing.

From marine components to automotive parts and construction materials, polyester resin provides a versatile, cost-effective solution for many industries, offering reliable performance and durability.